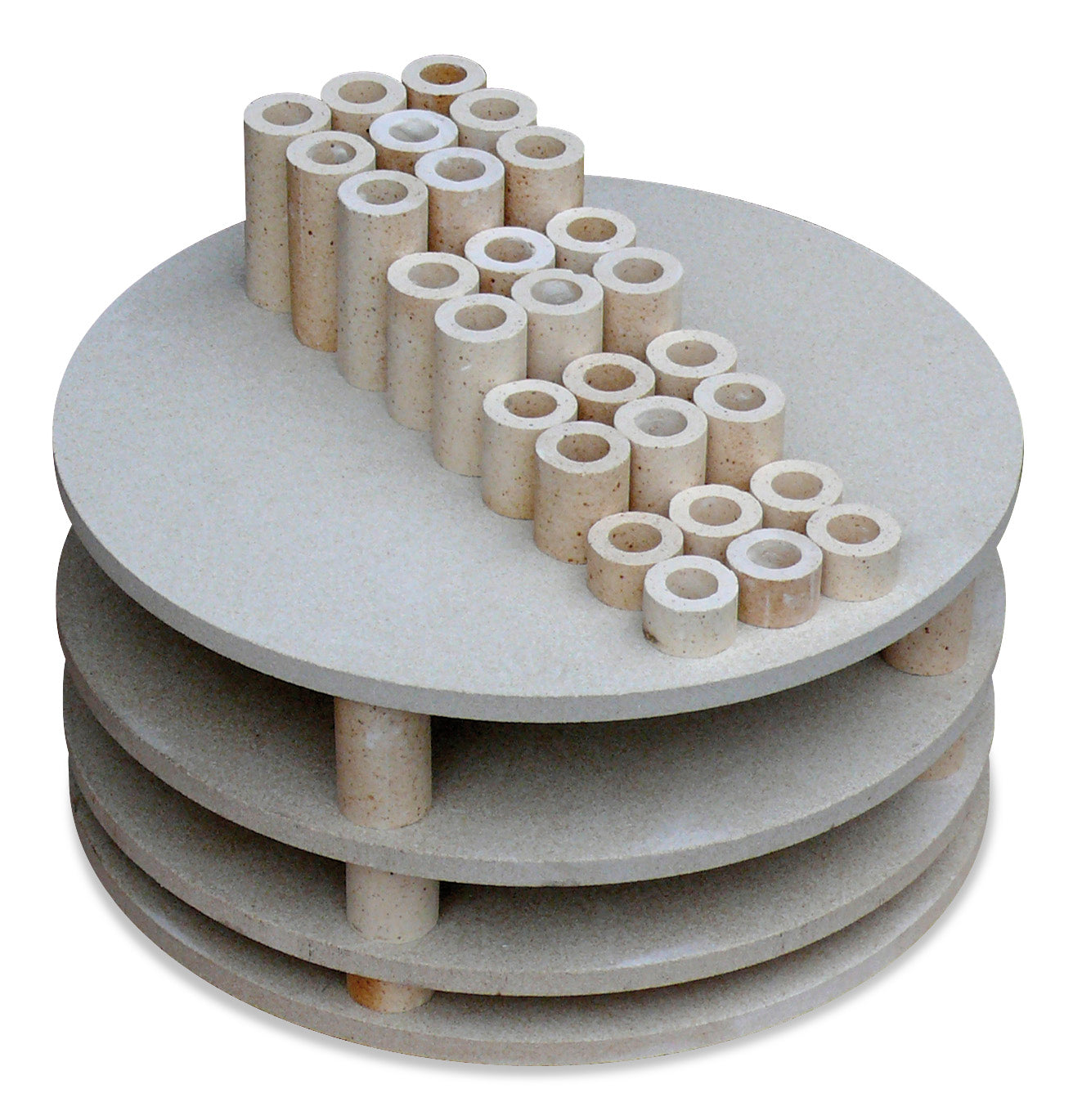

Furniture Kit 4

This kit includes four 21.3" diameter Cordirex 128 kiln shelves and three sets of hollow posts (3 each of 63/64”, 1 31/32”, 2 61/64”, and 3 15/16”). Each post set features multiple height options, ensuring secure stacking, optimized airflow, and reliable support for a wide range of firing loads.

Pickup available at Rohde Kilns Warehouse - Greensboro

Usually ready in 5+ days

Furniture Kit 4

Rohde Kilns Warehouse - Greensboro

938 Reynolds Place

Greensboro NC 27403

United States

Choose options

Mykiln App

Your Digital Firing Companion

Monitor live kiln status, create and send programs directly from your smartphone, and receive real-time notifications on firing progress or alerts. Archive firing curves, add your own notes and images, and track energy consumption — all in one place. Whether you’re in the studio or on the go, MyKiln keeps you connected to your craft.

Why Artists Choose The Ecotop

Compact and energy-conscious, Ecotop kilns are designed for hobbyists, educators, and small studios who want professional results in limited space. Crafted with quality materials and built for reliable firings, they give artists the confidence to create without compromise.

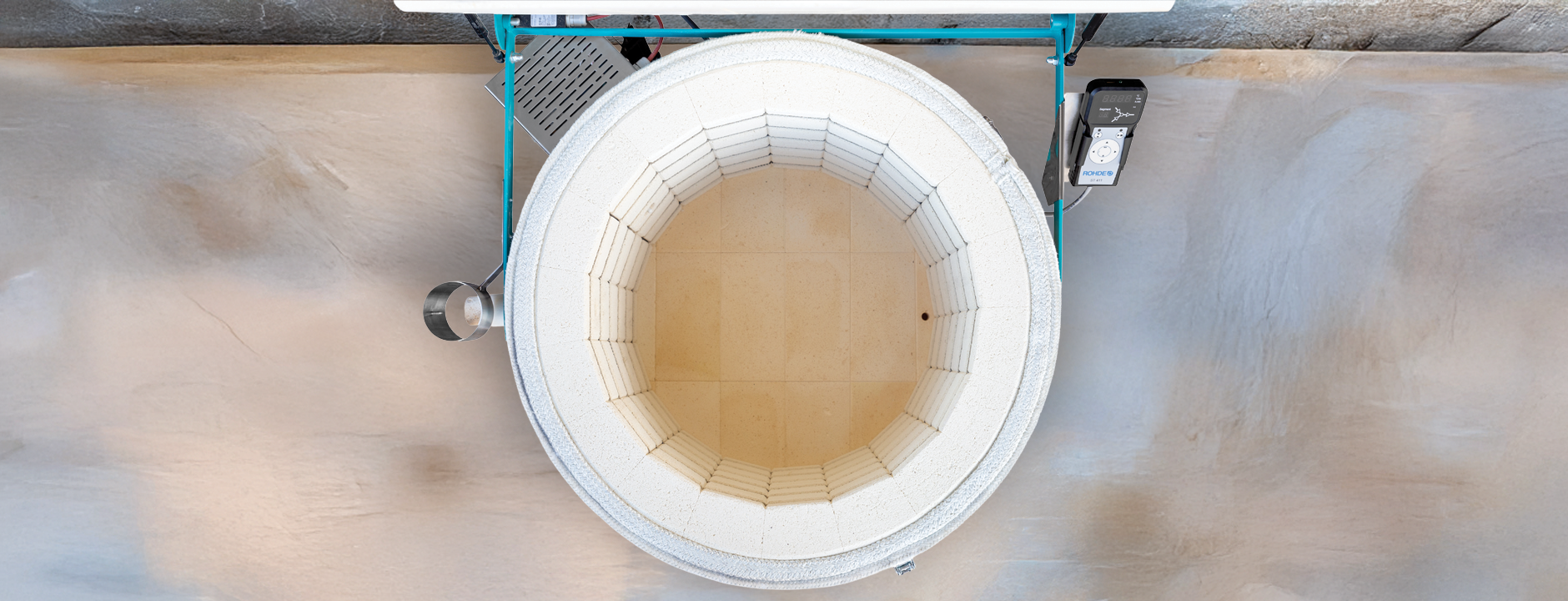

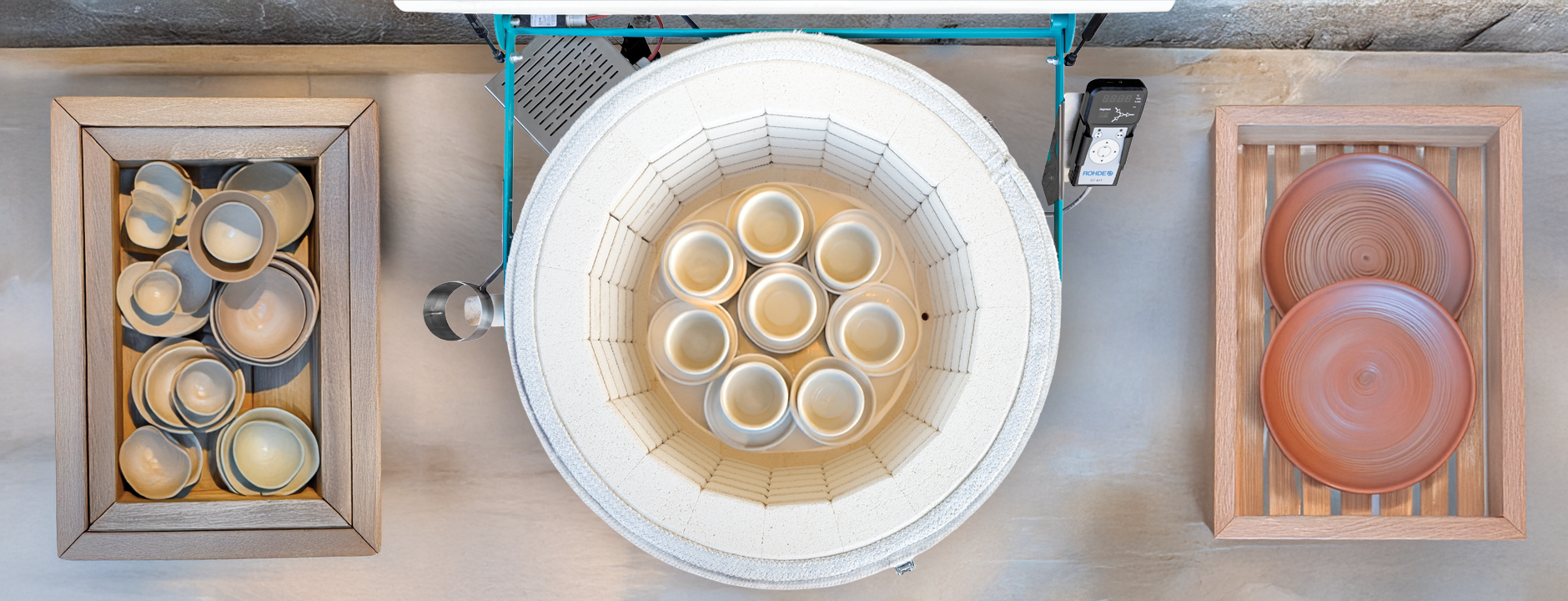

Toploader in Action

From an empty chamber to fully filled with ceramic work—the Ecotop is made to support every step of your creative process.

Before

After

learn more about the ecotop

Need help?

Frequently Asked Questions

General Questions

Before using your new ROHDE kiln, review the following guidelines to ensure safe and proper installation.

- Choose the right size chamber. Avoid selecting a firing chamber that’s too small. Make sure you have enough space for loading and unloading your kiln, as well as for handling kiln shelves and furniture.

- Place the kiln on a stable, level surface (± 1/8 inch). An uneven or unstable surface can cause the internal stacking structure to shift or become unstable during firing.

- Use flame-retardant materials for nearby floors, ceilings, walls, and partitions (Class B1 building materials or equivalent).

- Maintain proper clearance.

Front-loading kilns: leave at least 10 inches of space on all sides.

Top-loading kilns: leave at least 20 inches of space on all sides.

For front-loaders, ensure there’s additional access behind the kiln to service or replace heating elements. - Keep combustible materials away. Maintain a distance of at least 20 inches from any flammable materials such as wooden shelving, and allow sufficient clearance to the ceiling.

- Ensure proper ventilation. The kiln must be located in a well-ventilated area. If natural ventilation is insufficient, install an external fresh air supply and make sure exhaust gases are safely vented.

- Follow local building and safety codes, especially in public spaces such as schools or community centers. In some cases, you may be required to install a separate, restricted-access firing area.

Permissible environmental conditions:

- Ambient temperature: 23°F to 86°F (-5°C to +30°C)

- Relative humidity: Below 80% (non-condensing)

Each ROHDE kiln includes a power cable approximately 7.5 feet long for connection to the main power supply. Power requirements and current ratings are listed on the kiln’s nameplate. The power cable and outlet must be rated according to the kiln’s electrical specifications.

If you have any questions about the installation or wiring, consult a licensed electrician who can account for local conditions such as cable length, wiring method, and electrical load. The outlet should be positioned close to the kiln.

Important Safety Notes:

- Never use an extension cord or power strip to operate the kiln.

- The power cable must not touch any part of the hot kiln surface.

Although rare, damage can occasionally occur during transportation. While our packaging is designed to provide maximum protection, handling during shipment is outside our control. For that reason, it’s essential to inspect your kiln immediately upon delivery.

Check for any visible signs of damage to the packaging or the small cardboard box placed on top (used to prevent stacking). Each kiln is shipped with a ShockWatch indicator label on the exterior—if it has been triggered, the kiln may have been exposed to excessive vibration during transport.

If you notice any damage or a triggered ShockWatch label, inspect the kiln with the driver present. Unpack the pallet, check for visible damage, and note any issues directly on the delivery receipt. Be sure the driver signs your remarks. If the kiln appears severely damaged before unpacking, you may refuse delivery—it will be returned to the sender for resolution with the carrier.

Take photos of the damage and all shipping documents, and report the issue to both the shipping company and your local ROHDE specialist within 24 hours of delivery. All shipments are insured, but claims can only be processed if damage is reported immediately. Claims submitted more than 24 hours after delivery cannot be accepted.

Before operating your kiln, remove all items from inside the chamber and peel away any protective film from the exterior surfaces, ensuring no residue remains. Review the operating manual carefully for both the kiln and controller to become familiar with all functions and safety procedures.

You’ll also find detailed instructions on transportation, installation, setup, and the recommended initial (first) firing in the manual.

For electric kilns, gases do not come from the kiln itself but from the materials being fired. Every firing—whether bisque or glaze—produces exhaust gases from the clay and glazes, which may include small amounts of carbon monoxide, nitrogen oxides, sulfur oxides, and other compounds.

To ensure safety, the kiln room must have adequate ventilation during every firing. In many cases, opening a window provides enough airflow, but the window must remain open for the entire firing cycle (a window contact switch can help ensure this).

If window ventilation is not allowed, or if local regulations—such as those for schools or public buildings—require a dedicated exhaust system, a ventilation engineer should design and install one. Always follow the applicable local building and safety codes for your facility.