High-Volume Firing, Built for Constant Production.

Ecotop 300 S

The Ecotop 300 S delivers a large 10.6 cu ft chamber designed for studios that fire often and at scale. With ROHDE’s advanced insulation, precise control system, and durable construction, it ensures consistent performance across heavy workloads. Its efficient design supports reliable, repeatable results, making it an ideal choice for production-focused ceramic workshops.

Reversible Kiln Stand

True Cone 10

2- Layer Insulation

All Ecotop kilns come with the TR511 controller.

Pickup available at Rohde Kilns Warehouse - Greensboro

Usually ready in 5+ days

Ecotop 300 S

240 V 3PH - NEMA 15-50

Rohde Kilns Warehouse - Greensboro

938 Reynolds Place

Greensboro NC 27403

United States

Peepholes: 1

Application Temp: 2352°F

Maximum Temp: 2408°F

Weight:

Download the Ecotop Manual >>

Download the Controller Manual >>

The largest Ecotop models: Ecotop 200 S, Ecotop 250 S, Ectop 300 S are separable for easier installation and assembly on site. You can split the main body into two sections.

Choose options

Your Digital Firing Companion

MyKiln App

Monitor live kiln status, create and send programs directly from your smartphone, and receive real-time notifications on firing progress or alerts. Archive firing curves, add your own notes and images, and track energy consumption — all in one place. Whether you’re in the studio or on the go, MyKiln App keeps you connected to your craft.

Why Artists Choose The Ecotop

Compact and energy-conscious, Ecotop kilns are designed for hobbyists, educators, and studios who want professional results in limited space. Crafted with quality materials and built for reliable firings, they give artists the confidence to create without compromise.

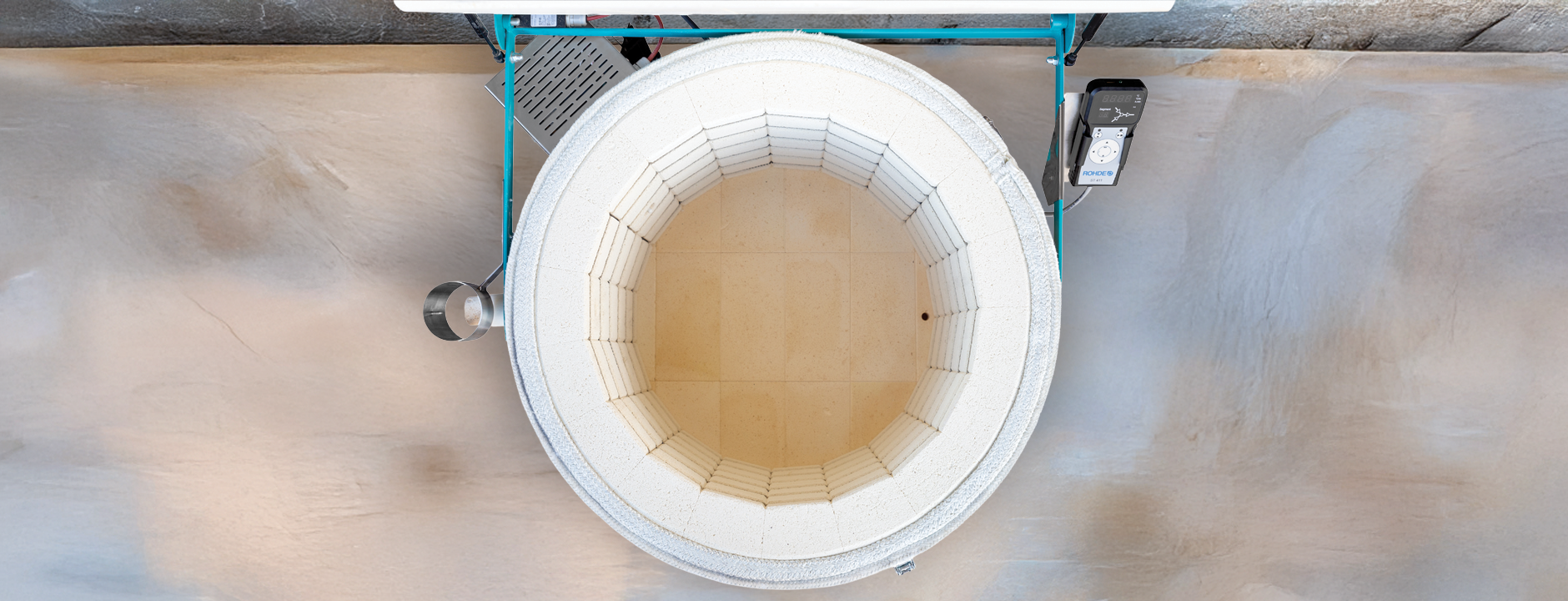

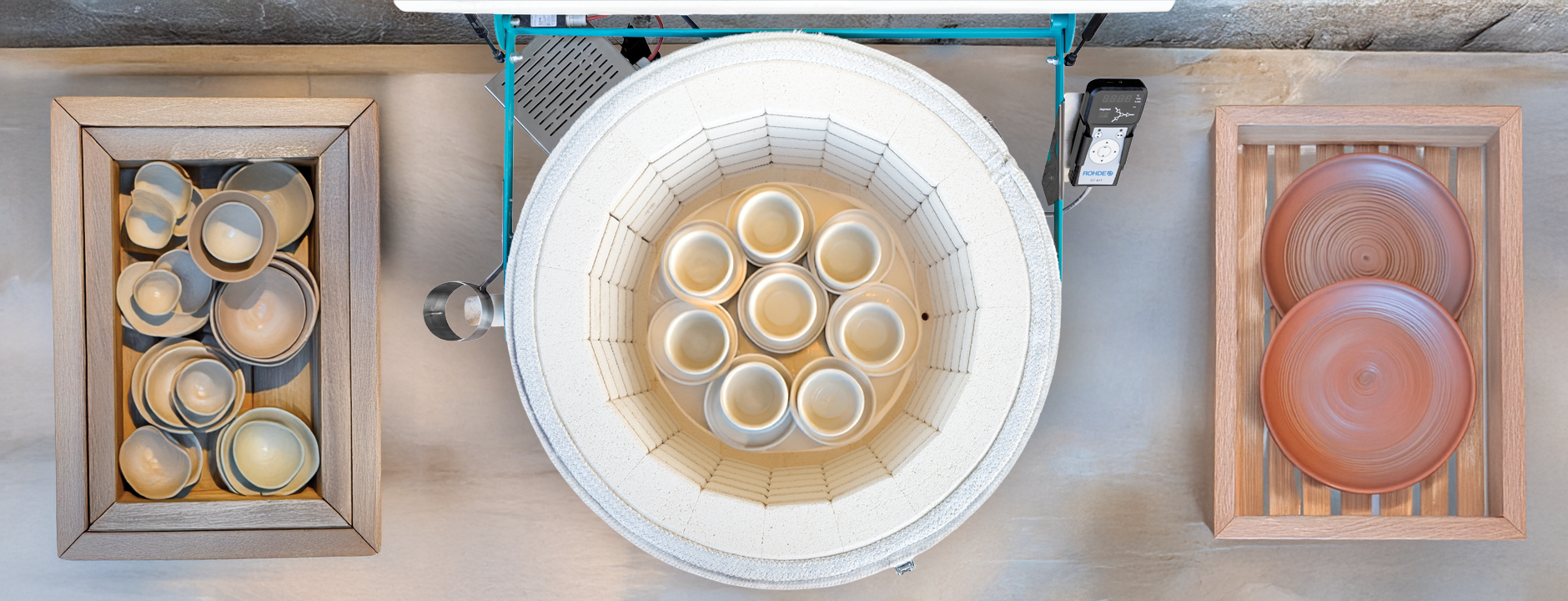

Toploader in Action

From an empty chamber to fully filled with ceramic work—the Ecotop is made to support every step of your creative process.

Before

After

learn more about the ecotop

Need help?

Frequently Asked Questions

General

A few points should be checked in advance to ensure the safe operation of your new ROHDE kiln. Prepare the operating location according to the following installation instructions:

- Allow adequate space around the kiln for loading and unloading the kiln as well as storing kiln shelves, posts, cones, etc.

- Position the kiln on a clean, level surface [+/- 1/8” (3mm) variance is acceptable]. If the kiln is placed on an unstable surface, the stacked furniture inside may become unstable as well.

- The floor, ceiling insulation, walls, partition walls, cladding, etc., must be made of Class A fire-rated materials. Examples include concrete, fiber cement board, fire-rated gypsum board, clay brick, and metal.

- The distance between the kiln and the walls, etc., should be at least 20” (50 cm) for top loaders. For front loaders, allow 10” (25 cm) on the side opposite the control panel, at least 20” (50cm) maintenance area behind the kiln (for replacing elements) and safe working clearance of 36” (90cm) for up to 240VAC, or 42” (1067cm) for up to 600VAC] in the direction of access into the control panel.

- No combustible materials (wooden shelves) may be within 20” (50 cm) of the kiln, measured horizontally. A vertical space of 40” (100cm) above the kiln to the ceiling must also be maintained.

- Make sure that the operating location is very well-ventilated. Otherwise, a fresh air supply must be installed. It is also necessary to discharge (vent) the exhaust gases appropriately.

- The applicable local regulations must be observed. Please consult with local authorities.

Please adhere to the permissible ambient conditions:

Permissible environmental temperature: 23°F to 86°F (-5°C to +30°C)

Relative humidity: <80%, non-condensing

Each ROHDE kiln comes with a corresponding cable [length approx. 7.5 ft (2.3 m) for the mains connection. The corresponding amperage can be found on the nameplate. The power cable and receptacle outlet must be sized according to the connection and performance data of the kiln.

If you have any questions, please contact a local electrician who can consider the local conditions (cable length, type of cable installation, etc.). The receptacle outlet should be close to the kiln.

Never use an extension cord or multi-outlet adapter.

The mains supply cable must not come into contact with the hot kiln.

Would you like to install a new electrical outlet in advance or find out about the amperage values? You can find the required information under the heading “Technical data” for the relevant kiln on our website.

Kilns with plugs (as opposed to hard-wired) should only be operated from a robust receptacle outlet. Each kiln should be powered by its own dedicated circuit.

Unfortunately, in rare cases, the kiln gets damaged during transportation. We have optimized our packaging to protect the kiln, but have little control over its handling during transportation. It is therefore important to check the kiln upon delivery.

Is the packaging of the kiln damaged, or is the small cardboard box (to prevent stacking) on top of the kiln dented? We always deliver our kilns with a ShockWatch label, which is clearly visible on the outside of the delivery. This can be used to check whether the kiln has been exposed to strong vibrations during transportation.

Please check these points upon delivery:

- If the packaging of the kiln is found to be damaged upon delivery or the ShockWatch device has been triggered, unpack the pallet with the delivery driver still present and check the goods again for damage. On the delivery paperwork, record details of any kiln damage detected and have the driver countersign your remarks. You can refuse to accept the delivery if you notice severe damage before unpacking. The kiln is then returned to the sender, who takes over the resolution with the shipping company.

- A few photos of the damage and the delivery documents are very helpful for the local specialist. Transportation is always insured; however, this insurance only applies if the damage is reported immediately, typically within a maximum of 24 hours after delivery.

- Please keep a copy of the damage claim or take a photo of it and inform the shipping agency and local specialist immediately of the damage. Claims made more than 24 hours after delivery may not be considered by the insurance company and therefore may not be accepted.

Before commissioning your kiln, remove all objects from the kiln and all protective films from the outer surfaces without leaving any residue.

Familiarize yourself thoroughly with the operating instructions for the kiln and the controller. You will also find further information on transportation, installation, and commissioning, and the recommended initial firing here.

The basic rule for electrically operated kilns is that gases never emanate from the kiln, but do emanate from the fired ware.

Every firing with ceramic ware produces exhaust gases, regardless of whether it is a bisque or glaze firing, regardless of the type of clay or glaze, regardless of the manufacturer.

This kiln exhaust air may contain traces of carbon monoxide, nitrogen oxides, sulphur oxides, fluorine compounds, and smoldering substances from organic additives in the glazes or ceramic bodies. At the outlet into the exhaust air duct, these are strongly diluted (approx. 1:10) with room air and cooled down at the same time.

It must therefore be ensured that there is sufficient room ventilation during the firing process in the kiln. In some cases, this can be achieved by means of window ventilation.

It must be ensured that windows remain open at all times during the firing process (e.g., by fitting a window contact switch).

If window ventilation is not permitted or the requirements (public facilities, schools, etc.) stipulate a separate ventilation system, this must be planned and installed accordingly. Ask a ventilation engineer about this.

In both private and public facilities, the applicable regulations of the respective jurisdiction must be observed. Further technical information is available on request.

Please view this blog.

Yes, each kiln room should have at least one smoke detector. More importantly, optimum air ventilation must be provided. If this is not the case, or if the discharge of the exhaust air is impaired due to a mechanical or electrical fault, smoke detectors could be triggered. Releasing the exhaust air from a hot kiln can lead to temperature fluctuations in the room that could trigger fire alarms.

Full Specifications

Full Specifications Which voltage and/or phase should I select?

Which voltage and/or phase should I select?